Liquid load securing, sloshing and “ADR” legislation

“Don’t be baffled, don’t be sloshed, use liquid load securing”

Dr. ir. Erik Jeroen Eenkhoorn

Technical scientific designer (PhD, MSc, MBA)

Hengelo (O), The Netherlands

ABSTRACT

The behaviour of bulk liquids during their transportation remains largely obscure for the public at large. This is to a large extent caused by the non-transparency of the mobile tanks these liquids are transported in. Besides drivers of tank trucks, or of trailers loaded with a tank container, few people are hence aware of the adverse safety effects of sloshing liquids during their transportation. Furthermore, many of those few being aware, erroneously accept “baffle plates” to be the adequate, scientifically “proven”, mitigation safety solution. Such acceptance is primarily based on such baffle plates having been made mandatory for mobile tanks, used for the transportation of bulk liquids classified as “dangerous”, by law for many decades. The securing of any kind of load, except bulk liquid loads, prior and during their transportation has simultaneously received much attention and has become subject to increasing mandatory requirements. Scientific research recently confirmed the possibilities and the attractiveness of securing bulk liquid cargoes prior and during their transportation. Securing of bulk liquid loads for their transportation may be desired to be applied in practice but raises questions on such being allowed or not, and if allowed; on what (mandatory) conditions. This paper aims at improving the awareness of the adverse consequences of liquids behaving dynamically during their transportation and aims at creating acceptance of the many spectacular scientifically proven findings of the research hereto. Furthermore, this paper aims at providing a basis for further discussion on the merits of bulk liquid load securing, the evanescent baffle plates and the desirability to (legally) allow the safety and sustainability of bulk liquid transportation to be increased even if legislation would require amending to allow this.

KEY WORDS

Liquid load securing, Cairbag, sloshing, dampening, force-based versus energy-based fundamentals, safety of liquid transportation, mitigation of severity of accidents., ADR, ADR Contracting Parties and ADR Participants, UNECE ITC.

AWARENESS AND ACCEPTANCE Serious and significant (safety) improvements on a topic rooted in society such as “liquid transportation” require a process commencing with creating awareness hence by the identification of “something disturbing”, a “concern” or a “problem” and by “alternatives”, “options”, “changes” being possible. Next is the acceptance thereof. This process shall happen in people’s heads and minds and shall result in a dedicated sustainable mission to mitigate or even eliminate the disturbance. Such mission shall be adopted and nursed by the highest authorities, matching the societal status of the challenge, to become successful.

Serious and significant (safety) improvements on a topic rooted in society such as “liquid transportation” require a process commencing with creating awareness hence by the identification of “something disturbing”, a “concern” or a “problem” and by “alternatives”, “options”, “changes” being possible. Next is the acceptance thereof. This process shall happen in people’s heads and minds and shall result in a dedicated sustainable mission to mitigate or even eliminate the disturbance. Such mission shall be adopted and nursed by the highest authorities, matching the societal status of the challenge, to become successful.

The mission to increase the safety of liquid transportation requires one to be aware and accept that:

• Liquids partially filling a mobile tank these are transported in, slosh.

• Sloshing has adverse safety consequences. And generally, makes liquid transportation “a challenge” for “participants” like truck drivers, even in normal transportation conditions.

• That this has been recognized, but that this recognising has resulted only in mandatory requirements for liquids classified as “dangerous”. Sloshing however, has equal repulsive safety effects on non-dangerous liquids.

• Accidents involving bulk liquid transportation still happen, while the source of liquid dynamics as a possible cause is either not recognized or wrongly judged. Maybe there are not many accidents but those happening, are of the most serious, severe and undesirable category.

• Load securing, as is mandatory for virtually every cargo, can now also be applied for bulk liquids. And, that load securing does increase the safety of transportation.

• That the safety of liquid transportation can and therefore should be increased. “Zero” bulk liquid transportation related accidents shall be the target of all stakeholders, including legislative authorities.

• That “liquid load securing” and “slosh mitigation” are two fundamentally different topics. Slosh mitigation is not the same as liquid load securing. All load securing is fundamentally “force-based”, slosh mitigation is “energy-based”.

• That slosh mitigation using baffle plates, as is mandatory by the “ADR”, is not sustainable and the use thereof conflicts with various legislation other than the “ADR”, including such legislation aiming for sustainability.

Unfortunately, “awareness” requires understanding of the base scientific principles, fundamentals such that these become accepted. The next (short), rather “scientific”, section aims at creating the essential understanding of liquid dynamics as occur in tank trucks and tank containers.

SLOSHINGOF BULK LIQUIDS

Mobile tanks for the transportation of liquids are never 100% liquid filled, for example, as:

• Allowances are to be made for thermal expansion, overfill protection, foam/froth build-up, air or vapour content of liquid, etc.

• Legislation does not allow a 100% fill of the mobile tank, refer like “ADR Article 4.3.2.2.: Degree of filling”.

• A “client” does not require a volume as large as may be contained by the mobile tank,

• There are more than one (off-)loading addresses in one shipment,

• A full load may exceed the legally mandatory maximum (axle(s) or total) truck load in any territory in which the transportation takes place.

Mobile tanks partially filled with liquid also contain (vapour filled) air. This “free” air provides no stability against liquid movements. As mobile tanks are never 100% liquid filled, these liquids are unquestionably subject of movements relatively to the mobile tanks during their transportation. Such movements of liquids may vary from semi-static free liquid surface instability (while driving at a constant speed in a straight line) to “erratic, turbulent, random “sloshing” in more complex driving conditions.

The scientific basis of “sloshing” (short version)

There are fundamental differences between 100% and non-100% liquid filled mobile tanks. When a 100% liquid mobile tank brakes , the liquid compresses commencing at the front plate of the tank. A brake related pressure wave progresses with (about) the speed of sound (i.e. a “very high” speed) through the liquid to the back plate. This compression of liquid firstly involves a neglectable movement of liquid relatively to the mobile tank and secondly ensures virtually all kinetic energy of the liquid to be transferred via the tank and truck to the truck brakes. The energy absorbed by the compression of the liquid is transferred to the brakes at the final stage of the braking as the truck reaches a stand-still. Tank truck and liquid cargo come to a stand-still simultaneously.

When a non-100% liquid filled mobile tank brakes, the liquid first must move towards the front plate of the tank. Liquids remaining at the original pre-brake speed start to move relatively to the braking mobile tank these are transported in. Liquids are not subject to friction forces at the contact surface with the inner tank wall. (There may just be some “boundary layer”, i.e. “Reynolds” effects). There is hence also no immediate compression of the liquid, as in case of a 100% filled tank. The only initial pressure built-up is the hydrostatic pressure, starting at the front plate, as the liquid level rises there first.

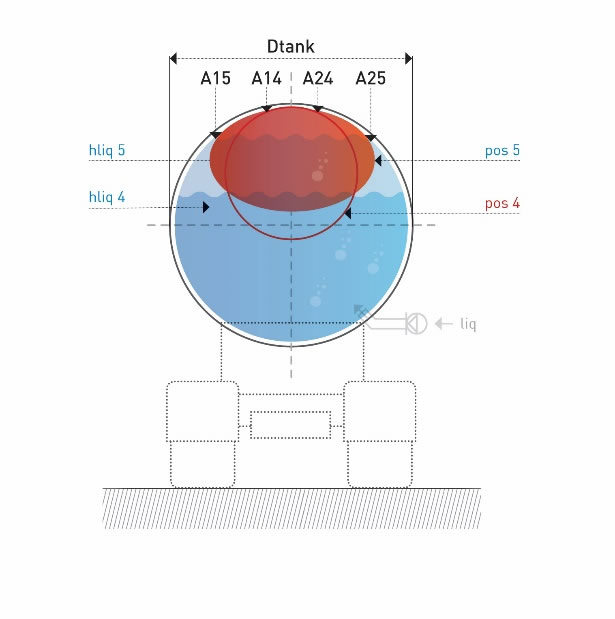

Liquids partially filling a mobile tank are subject to two primary modes of behaviour: a “transfer of energy” mode and a “pendulum” mode. As the inner walls of a mobile tank do not (or hardly) exercise friction forces on a liquid content they may contain, de- and acceleration forces have to be transferred from the means of transportation through the liquid / wall contact at the front and rear plates or discs of the mobile tank. (see pictures 1).

Liquids partially filling a mobile tank are subject to two primary modes of behaviour: a “transfer of energy” mode and a “pendulum” mode. As the inner walls of a mobile tank do not (or hardly) exercise friction forces on a liquid content they may contain, de- and acceleration forces have to be transferred from the means of transportation through the liquid / wall contact at the front and rear plates or discs of the mobile tank. (see pictures 1).

Pictures 1, Two snapshots of dynamic liquid conditions. One (at top) showing the transition of the “pendulum” to the energy transfer” phase, one (at bottom) showing maximum energy transfer stage.

As the liquid is not stable in such position, the “pendulum” mode commences. The “transfer of energy” duration is generally, depending on the (de- or) acceleration level, (much) shorter than the pendulum or “wave” motion. To ensure sufficient energy to be transferred in the “transfer of energy” stage, the liquid compresses (slightly), hence the (temporary) near vertical liquid surface in the pictures 1. The plate or disc opposite the plate or disc transferring energy to or from the liquid restricts the liquid in its flow relatively to the means of transport and thereby enforces the “pendulum” motion, energy of the liquid is dissipated (i.e. converted into heat, “lost”).

The (kinetic) energy of liquids, required to be transferred during a brake process in a non-100% filled mobile tank will hence take much more time as compared to such energy transfer in a 100% filled tank. A tank truck or truck with tank container comes to a stand-still long before the liquid has lost its kinetic energy. The liquid remains sloshing, until all its energy has been dissipated. The brakes of the truck cannot and do not absorb this energy, as the truck stands still at this stage!

The scientific bases of “slosh mitigation”.

Liquids may slosh trough sometimes as much as 50 wave motions between the mobile tank endplates before coming to a stand-still in case of a tank truck braking. This is supported by many scientific test results confirming liquids dissipating about 2-3% of their energy in one wave motion. Refer [3].

Figure 2, Baffle plates in a mobile tank.

Figure 2, Baffle plates in a mobile tank.

Mobile tanks with internal baffle plates, see figure 2, cause liquids to built-up pressure against each baffle plate (except at the openings therein), in addition to the front or back plate of the mobile tank. This enables more energy to be transferred from the engine of the truck via the tank to the liquid and from the liquid via the mobile tank to the truck brakes. In addition to the energy dissipation in the boundary layer at the inner tank wall, the liquid dissipates extra (kinetic) energy passing through the openings (“holes”) of the baffle plates. This energy dissipation, identically to liquid dynamics, is happening continuously during the entire duration of the transportation. The energy is dissipated as the liquid forces itself through the openings in the baffle plates, and peaks especially during accelerating and braking. The quantity of energy being supplied by the truck engine or being absorbed by the brakes and the quantity of energy being dissipated by the liquid is strongly dependent on the liquid fill level of the tank and the number of, the cross-surface size and the position of the openings in the baffle plates. The “ADR” arbitrarily requires the cross-surface area of the openings to be 30% of the total tank cross-surface area and the tank volume in between baffles to be 7,5 m3 (max.).

A partial liquid fill of mobile tanks provided with baffle plates also results in the two primary modes of behaviour: a “transfer of energy” mode and a “pendulum” mode (see above), identically to mobile tanks without baffles. In addition to “total-tank-length”, “total liquid load volume” waves as in mobile tanks without baffles, there are also “in-between-baffles”, “part-of-the-liquid load volume” waves in mobile tanks provided with baffles. The oscillating frequency “ω” (ω = √(g/L), ref [3]) increases in tank segments with a shorter length. In case a mobile tank is for example provided with 5 baffle plates, the length of each section in between baffles is 1/6 of the tank length and the frequency of the “in-between-baffles” waves becomes almost 3 times higher as the “total-tank-length” waves . The “part-of-the-liquid load” volumes of liquid between baffles (1/6 of the total liquid volume in the example mobile tank) go through 3 times as many “in-between-baffles” wave motions during accelerating or braking, as compared to the number of waves in a mobile tank without baffles. These are the prime fundamentals of “slosh mitigation” by baffles and the acclaimed enhancements thereof on tank truck braking.

Tank trucks or trucks transporting tank containers driving at a constant speed through curves remain constant in the total (truck and liquid load) energy content. Driving through curves does hence not require energy dissipation. As baffle plates function through energy transfer and dissipation, baffle plates, by definition, cannot and do not provide any added (safety) value in driving through curves nor in “swerving” driving conditions. This is also the main reason why baffles are only positioned perpendicular to the driving direction of a mobile tank, never parallel to it.

LIQUID LOAD SECURING Liquid load securing means: Fixation of the entire liquid load in the mobile tank it is (to be) transported in such that it does not move relatively to the mobile tank. “Slosh mitigation” and “liquid load securing” are not identical, they are actually: opposites. A liquid load is either secured and consequently does not slosh or the liquid load is not secured and thus sloshes. There is hence a choice in the conditions of liquid transportation, it is “one or the other”. Liquid load securing can be affected using any of the various, fundamentally different, alternative methods available thereto. Refer [1], [16]. Two examples of such methods are provided hereinafter:

Liquid load securing means: Fixation of the entire liquid load in the mobile tank it is (to be) transported in such that it does not move relatively to the mobile tank. “Slosh mitigation” and “liquid load securing” are not identical, they are actually: opposites. A liquid load is either secured and consequently does not slosh or the liquid load is not secured and thus sloshes. There is hence a choice in the conditions of liquid transportation, it is “one or the other”. Liquid load securing can be affected using any of the various, fundamentally different, alternative methods available thereto. Refer [1], [16]. Two examples of such methods are provided hereinafter:

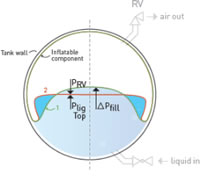

• One method uses a “fixed volume” inflatable component, see figures 3. This component is made of a thermoplastic, elastomer or rubber material which is inflated to a pressure slightly above the maximum pressure, which can or may occur in the liquid during its transportation. The working pressure (100 to 500 millibar) and the high “Young’s modulus” of the component material ensure the rigidity and shape retention of the component and the transfer of all occurring forces in between liquid and inner tank wall.

Figures 3. Cross-section of a horizontal cylindrical tank containing an inflated fixed-volume component showing the position and form changes during the liquid filling of the tank.

• Another method of liquid load securing uses a “variable volume” inflatable component, see figures 4. The contact surface of this component with the liquid top surface is sufficiently tensioned using the pressure differentials and pressure changes during liquid (off-)loading and normal transportation conditions and using “excess” component material creating tensioning “flaps” at the inner tank wall.

Figures 4. (left). Shows a cross section of a horizontal cylindrical tank in which a variable volume component is present. The contact area of the liquid and venting component increases during the liquid filling of the tank from position "1" through "2" to position "3". Figure 5 (right) The contact area between the variable volume component and the liquid surface changes from a curved ("2") to a (near) horizontal shape ("1") when the liquid filling process ends.

Figures 4. (left). Shows a cross section of a horizontal cylindrical tank in which a variable volume component is present. The contact area of the liquid and venting component increases during the liquid filling of the tank from position "1" through "2" to position "3". Figure 5 (right) The contact area between the variable volume component and the liquid surface changes from a curved ("2") to a (near) horizontal shape ("1") when the liquid filling process ends.

Both liquid load securing methods are “force-based”, identical to all other methods of load securing using for example “tension belts” or “tarpaulins”.

Both liquid load securing methods are “force-based”, identical to all other methods of load securing using for example “tension belts” or “tarpaulins”.

THE INCREASE OF SAFETY OF TRANSPORTATION RESULTING FROM LIQUID LOAD SECURING

The safety of bulk liquid transportation is increased both for normal day-to-day driving conditions as well as through mitigation of the number and severity of accidents.

Evaluation of safety benefits for normal driving conditions

Liquid load securing affects virtually all “normal” day-to-day transportation conditions including driving through curves and braking. This section provides some of the results.

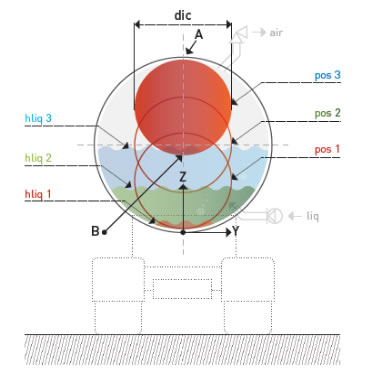

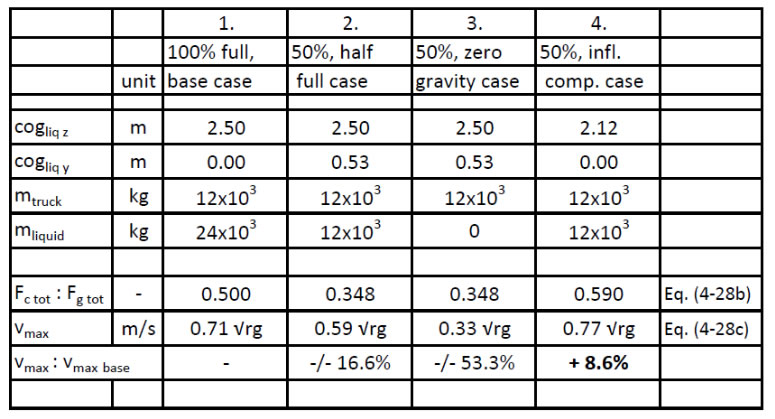

• Driving through curves

The maximum speed “Vmax”, defined as: the speed at which the truck can drive through a curve with radius “r” and just does not keel-over is provided for 4 different conditions. The base case (Table 5, column “1”), is a truck with a 100% liquid filled tank. The maximum speed of a 100% liquid filled tank truck drops by some 16,6% in case (“2”) the truck is half liquid filled (i.e. 50% full) and the center of gravity of the liquid moves semi-statically to its most outward position. The maximum speed, with a 50% liquid filled tank, drops much further, to 53,3%! in case (“3”) when the liquid progresses from a semi-static mode to a “roll-over wave and temporarily weightless” mode. Note: This condition was recorded at one of the test drives at the TÜV tests. [12]. A liquid load securing application, in the 50% liquid filled case (“4”), ensuring the center of gravity of the liquid to remain at its lowest point results in a 8.6% higher maximum speed, as compared to the 100 % filled tank condition in case 1 and a 100+ % higher maximum speed, as compared to the 50 % filled tank turbulent condition in case 3.

C

C a

a se 1: 100% liquid filled Case 2: 50% filled, semi-static

se 1: 100% liquid filled Case 2: 50% filled, semi-static

Cas e 3: 50% fill, roll-over wave Case 4: 50% fill, secured

e 3: 50% fill, roll-over wave Case 4: 50% fill, secured

Figures and Table 5. Maximum Speed in Curves for different liquid behaviour conditions cases refer to figures above. Legend:

• Case 1: The base case a 100% liquid filled mobile tank.

• Case 2: The semi-static, 50% liquid filled mobile tank case.

• Case 3: The 50% filled mobile tank roll-over, weightless liquid case

•  Case 4: The 50% liquid and 50% inflated component filled case.

Case 4: The 50% liquid and 50% inflated component filled case.

• Braking

The impact of liquid load securing on the braking performance of mobile tanks is such that the brakes perform identically compared to brakes of means of road transportation of any cargo other than liquid. Both cargo and means of transportation (tank truck) come simultaneously to a stand-still. This is very different in mobile tanks without load securing, even if such tanks are provided with baffle plates. Without load securing the liquids remain to slosh (even long) after the mobile tank has come to stand-still. The liquid cargo must “lose its kinetic energy” through internal dampening during a sloshing process. Remarkable hereby, and proven by (TÜV) testing, is that the brake distance of a tank truck with liquid load securing is longer at lower pre-brake speeds than of a similar truck and non-secured liquid cargo. This is the result of the brakes having to absorb the kinetic energy of the liquid cargo, in case of load securing, as well as of the truck. Without load securing the brakes only absorb the kinetic energy of the means of transportation, not of the liquid cargo. With liquid load securing the brake distance of a mobile road-going tank is equally long as the brake distance of any other truck of the same weight. Please note: Partially filled mobile road tanks without load securing will not and cannot decelerate safely at higher pre-brake speeds, their brake distance is considerably longer, especially in “emergency brake” cases with the mandatory specified rate of 0,8 g m/s2.

Accident related avoidance and reduction of severity benefits.

• Accident avoidance

As shown above (table 5) a mobile road tank partially filled with a liquid load can drive at a (much) higher speed through curves without such truck keeling over. At normal driving speeds of tank trucks, keeling-over is hence less likely to happen. As baffle plates are only installed perpendicular to the driving direction, see figure 2, these do not provide for any load restraining forces in sideward direction. Unfortunately, this is the only direction in which (tank) trucks keel-over! Equally, jack-knifing accidents of truck trailers are avoided by liquid load securing as the liquid cannot exercise forces perpendicular to the driving direction on the “king-pin” connection between the mobile tank and the engine truck.

Drivers of tank trucks without load securing, assess, based on personal experience, the intensity with which they brake “in a safe manner”. Even in case of emergency braking, they do not brake intensively (i.e. with a deceleration of “0,8g m/s2”) nor continuously, to bring the mobile tank to a stand-still with the shortest possible brake distance. The liquid behaviour, when not secured, does not allow for such intense braking. Liquid load securing allows for maximum braking and shortest possible brake distances even in the most extreme conditions.

• Mitigation of the severity of accidents

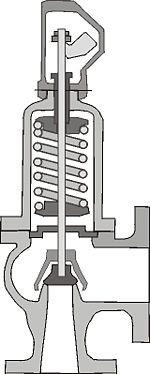

Securing liquid cargoes also mitigates the consequences of very serious accidents, especially such involving tank-trucks transporting (pressurized) liquefied gasses. The fluid dynamics associated with an immediate virtual stand-still of a tank truck in case of a head-to-tail accident, causes high-pressure spikes. Such high-pressure spikes occur at random, very localised and usually involve only a very small portion of the liquid surface. Such high-pressure spikes may also occur, at the position of the high-pressure safety valve. The pressure in the spike may be (much) higher than the set-pressure of the safety valve for a short but sufficiently-long-to-open-the-valve moment. The valve will open, by design, to relief the over-pressure, causing vapours from the tank to flow to the outside.

This generally is not noticed, the quantity of vapour is little, the duration of the relief is short and there is nobody near the valve when it happens. Except in cases when there is an external fire which occur (too) often in the onset of an accident. Such external fires often commence at the unprotected, single thin hulled, truck diesel tank, failing in the

Figure and picture 6; an over-pressure safety relief valve example (left) and an exposed single hull fuel tank of a truck (right) .

.

accident and the diesel catching fire. Such fires generally are short-lived as the quantity of diesel is relatively little but last long enough for the first pressure wave (with highest spikes) to hit the pressure safety relief valve. The opening thereof results in the relieved vapour flowing into the fire and catching fire. Such fires progress much quicker upstream as the vapour flows downstream out of the valve. The stem and disc of the safety valve become damaged by the fire and the valve therefore no longer "closes". The fire will now continue fueled by the unrestricted flow of gas from the tank via the damaged relief valve. The liquid gas remaining inside the tank will commence to heat-up and proceed to boiling, initiating a catastrophic BLEVE thereby. [17] The risks of exposure of tank components, especially the overpressure protection devices, to high, liquid dynamic based, pressures are eliminated by liquid load securing inflatable components.

LEGISLATIVE CONFINES

The transportation of bulk liquids is only subject to dedicated legislation when such liquids are classified as “dangerous” and when the transportation “crosses boarders”, i.e. is “international”. Such legislation is called:

EUROPEAN AGREEMENT CONCERNING

THE INTERNATIONAL CARRIAGE OF

DANGEROUS GOODS BY ROAD (The “ADR”)

The “ADR” commences as follows, (Quote: ADR main text)

THE CONTRACTING PARTIES,

DESIRING to increase the safety of international transport by road,

HAVE AGREED as follows:

“ (Unquote).

The UNECE and its “Inland Transportation Committee” (the “ITC”) are the custodians of this agreement.

The ADR is increasingly recognized, also and especially outside the European territory, as the suitable worldwide legislative basis for the safe transportation of dangerous goods. The term “European” will hence, as from 1st January 2021, be deleted from the Agreement title. The interesting question remains whether “safety” should become “sustainability” and whether the terms “International” and, or “Dangerous” should be deleted from the Agreement title? The ITC appears to be oriented in this direction, refer their quote:

UNECE Inland Transport Committee: quote:

“We work to promote sustainable transport which is safe, clean and competitive, through the development of freight and personal mobility by inland transport modes, by improving traffic safety, environmental performance, energy efficiency, inland transport security and efficient service provision in the transport sector.” Source: UNECE website.

As for the legislative aspects of load securing (and slosh mitigation) of liquids qualified as “dangerous” for their safe international transportation, there are three ADR related institutions of interest

• The UNECE, its administration including the “Inland Transport Committee”, the “Working Parties” and their Joint Meetings,

• The “Participants” as defined and specified by the ADR,

• The ‘Contracting Parties” having accepted the ADR.

Each of these three institutions has, ADR specified, possibilities as well as dedicated obligations regarding the agreed “desire to increase safety”. Before addressing the details hereto, the recommended mission is suggested first.

RECOMMENDED LEGISLATION IMPROVEMENTS

The introduction of a novel innovative application like the securing of bulk liquids, in a traditional and extensively regulated transportation market, which is subject to various laws, is bound to be confronted with a “generation gap”. Subject rules and laws are the result of processes which primarily evaluate safety consequences of transportation technologies introduced (long) before, based on sufficiently substantial and practical experience-based data. Such processes lasting mostly several decades. One requires thus also to be “aware” of such legislative “generation gap” and accept that novel innovative applications, especially “scientifically proven” ones may not and most likely will not precisely fit in their related regulation network at the moment of introduction of the innovation.

Two recommendations to improve current legislation, related to the transportation of bulk liquids, are made in this paper. As liquid dynamics and the safety related consequences thereof are inherent to the transportation of bulk liquids irrespective of such liquids also being qualified as “dangerous” or not, the first recommendation is that:

The transportation of all bulk liquids,

including liquids currently not classified as “dangerous”, shall comply with the ADR.

Secondly, the ADR is recommended to be allowed to be interpreted to at least allow for liquid load securing applications (as soon as possible) and, if necessary: to be amended thereto. The UNECE ITC may put the possibility of recommending or even requiring liquid load securing to become “mandatory” (in a longer term), on its agenda. Recommending liquid load securing or making such mandatory by law may be considered for example when the increase of the safety of the transportation of bulk liquids by securing such loads, is sufficiently proven over a sufficiently long period. Slosh mitigation by applying baffle plates, as is currently mandatory, shall be made evanescent simultaneously

• Recommended ADR amendment of load securing.

The ADR confirms the safety of transportation to increase by load securing most distinctly by ADR Article 7.5.7.1.

(Quote of ADR Annex “A” Article 7.5.7.1):

“ Where appropriate the vehicle or container shall be fitted with devices to facilitate securing and handling of the dangerous goods. Packages containing dangerous substances and unpackaged dangerous articles shall be secured by suitable means capable of restraining the goods (such as fastening straps, sliding slat-boards, adjustable brackets) in the vehicle or container in a manner that will prevent any movement during carriage which would change the orientation of the packages or cause them to be damaged. ….

Movement of packages may also be prevented by filling any voids using dunnage or by blocking and bracing. Where restraints such as banding or straps are used, these shall not be over-tightened to cause damage or deformation of the package. The requirements of this paragraph are deemed to be complied with if the cargo is secured in accordance with standard EN 12195-1:2010.

“ (Unquote).

Liquid load securing using “Cairbag” applications, meeting the ADR Article 7.5.7.1 requirements as specified in EN 12 195 as tested and certified by TÜV, are recommended to be considered “to be allowed”, if not “mandatory” by the current version of this article.

Recommended is furthermore, an amendment of ADR article 7.5.7.1 which shall result in this article to be clear, unambiguous and avoid any discussion on its range of applicability”:

“All loads shall be secured.”

This proposed text may be expanded for example by:

“All loads shall be secured. Such securing shall be affected prior to commencing transportation thereof and shall be guaranteed during transportation without any human attendance or interactions being required.”

And, or by:

“while allowing for securing condition monitoring continuously or at any desired time”.

This expansion may be desirable for example to facilitate law enforcement.

The justifying arguments for the suggested change of ADR Article 7.5.7.1 resulting in bulk liquid loads also having to be secured, are that:

• This increases the safety of the transportation of bulk (dangerous) liquids, as demonstrated in prior sections of this paper.

• This ensures compliance with EU legislation for example on the unnecessary waste of energy resulting in environmental damage being punishable by law. {4], [6]

• This ensures compliance with the EU directive on applying “Best Available Technology”, especially as the “Technical Readiness Level” is enough (TRL > level 7) thereto. [18], figure (5).

• This ensures compliance with vehicle legislation requiring the brakes of a means of transportation to absorb all (kinetic) energy of the means of transportation, its passengers and its loads during the brake process until the means of transportation comes to a stand-still. [5]

• This is economically attractive especially in view of the reduction in fuel consumption by the means of transport.

• This improves the sustainability of such transportation.

• Recommended ADR amendment of liquid slosh mitigation.

The ADR, legislatively incorrect, mandates baffle plates (only) to effect “slosh mitigation” in ADR Article 4.3.2.2.4.

The recommended amendment of ADR article 4.3.2.2.4 is:

"Liquid cargoes which only partly fill the mobile tank in which they are transported shall be secured in accordance with Article 7.5.7.1".

And possibly state in addition:

“Baffle plates are prohibited to be used”

(in mobile tanks build beyond 1 January 2022).

And, or:

“Baffle plates may be used provided liquid load

are secured in between such baffle plates.”

The justification for the above is ”scientific” rather than “political” based. The scientific basis is PhD research proven, supported by international known and reputable institutions and confirmed by full scale practical applications including such for ADR. [1], [7], [8], [10], [11], [12], [14], [15].

The ADR assumes sloshing to be at its most detrimental in case the liquid fills the mobile tank between 20% and 80%. The basis, nor the source of these arbitrarily chosen values (and earlier mentioned “7.500 liters (max.)” and “30% cross surface size of openings”) and assumptions are known hence not “auditable”. This also is not acceptable in European legislation.

Note: The ADR also serves as the basis for the “ADN” (for the transportation by ships). The ADN in its less than one page covering Chapter 4 “Provisions concerning the use of packaging’s, tanks, and bulk cargo transport units“ entirely specifies “(in section 4.1.2) the ADR (covering the same topics in Annex A, Part 4 in over 200 pages) to be applicable, including ADR section 4.3 (hence article 4.3.2.2.4, requiring the use of baffle plates). The harmonisation between the ADR and the AND fails here completely as for example “7.500 litres Max.” is not practical for internal tanker ships

OPPORTUNITIES OF “ADR participants”

ADR “participants”, many of them underwriting and implementing the “ECTA, responsible care” program and aiming at “zero accidents”, are very much aware of the safety improvements resulting from liquid load securing.

These ADR “participants”, confronted on a 24/7 basis with the adverse safety consequences of non-secured liquid loads, have several opportunities to increase the safety of bulk liquid transportation in a sustainable and legally accepted or acceptable manner. ADR “participants” may and must act autonomously under the provisions of the ADR, Annex A, section “1.4 Safety Obligations of the Participants”.

(Quote of section “1.4 Safety Obligations of the Participants”, 1.4.1 General Safety Measures” :)

“

- 4.1.1

The participants in the carriage of dangerous goods shall take appropriate measures according to the nature and the extent of foreseeable dangers, so as to avoid damage or injury and, if necessary, to minimise their effects. They shall, in all events, comply with the requirements of ADR in their respective fields. This general provision means that all participants must ensure that they take all necessary actions to reduce the risk of an incident involving dangerous goods.

” (Unquote)

And several “ADR participants” have done so. For example: the “Deutsche Erdoel Aktiengesellschaft, “DEA”, with “Franz Fischer Spedition”, one of the German transportation companies contracted by the DEA, and “Polyeco” in Greece. See also pictures 7.

Pictures 7; Franz Fischer ADR tank-truck(top) and “Polyeco” ADR tank-container (bottom picture), both with “Cairbag” liquid load securing provisions.

Pictures 7; Franz Fischer ADR tank-truck(top) and “Polyeco” ADR tank-container (bottom picture), both with “Cairbag” liquid load securing provisions.

• Appropriate measures.

ADR participants like the German DEA and Greek Polyeco took “appropriate measures to minimise the effects of foreseeable dangers”, in accordance with ADR article 1.4.1.1. They did so while complying with the “requirements of the “ADR”, as specified in quoted article. This compliance was and is not limited to technical specifications of the load securing provision like the materials used requiring to be chemically resistant against the liquid being transported but also requiring to be “anti-static”, while the pneumatics conform to “ATEX” requirements. The ADR and its provisions in Annex’s “A” and “B”, also provide for several encouraging motivations to consider the measures taken as “appropriate”, for example:

• Placing an inflatable component inside a mobile ADR tank is not prohibited by ADR. To the contrary, “dunnage bags “ (as may be used for liquid load securing) may be applied in accordance with article 7.5.7.1. as bulk liquids in mobile tanks may be qualified as “unpackaged goods”, as referred to in this article. ADR Articles 6.1.4.16 and 6.1.4.17 "bags made of plastic film to be used for securing the cargo and loading of trucks” allowing for and specifying dunnage bags for load securing, do not exclude the use of such bags for liquid load securing.

•  Liquid load securing products, using inflatable components inside the mobile tank, result in such tanks always being over 80% filled. The (baffle plate) requirement as in ADR article 4.3.2.2.4 is thus not applicable nor enforceable. Note: Article 4.3.2.2.4 specifies “fill rate” and not “liquid fill rate”. This allows the use of liquid load securing only, while not violating ADR Article 4.3.2.2.4 on baffle plates, in case the liquid fill rate is less than 80% (and over 20%).

Liquid load securing products, using inflatable components inside the mobile tank, result in such tanks always being over 80% filled. The (baffle plate) requirement as in ADR article 4.3.2.2.4 is thus not applicable nor enforceable. Note: Article 4.3.2.2.4 specifies “fill rate” and not “liquid fill rate”. This allows the use of liquid load securing only, while not violating ADR Article 4.3.2.2.4 on baffle plates, in case the liquid fill rate is less than 80% (and over 20%).

• The ADR generally, as in article 6.7.1.2 under 6.7.1. “Applicability and general rules”, encourages the application of innovations and may therefore be considered to allow for the implementation of bulk liquid load securing products, as it states:

“

[Alternative rules]

Allowing for the progress of science and technology, technical rules as in this chapter may be replaced by alternative rules. These alternative rules require to provide an at least equal safety and confidence level on all rules of this chapter in relation to the compatibility to the shipped liquids and to the capability of the transportation tank to withstand shocks, stresses and strains resulting from loads and fires.

“

• ADR Article 4.2.5.3, special provision "TP24" may also serve as a legal precedent. The participant (“Evonik”) requested provision in the ADR was strongly desired to increase the safety of the transport of hydrogen peroxide (with UN number 2014 or 2015) in a mobile tank. The "device that must prevent the leakage of an impermissible amount of liquid substance or the ingress of foreign substances even when the tank tips over", may be an inflatable component of a liquid load securing provision such that TP 24 and Article 4.2.5.3 are complied with. Any mobile tank may be provided with such device to ensure compliance in case a UN 2014 (/5) liquid would have to be transported. The device may (of course) then also be used during the transportation of liquids other than UN 2014 (/5).

OPPORTUNITIES OF ADR “Contracting Parties”

The ADR is an agreement between “Contracting Parties”, these “Parties” are responsible for the content of the ADR and the enforcement thereof. Like the “ADR Participants”, the “ADR Contracting Parties” also have possibilities and obligations to act autonomously.

Any “Contracting Party” has, by the conditions of the Agreement, the possibility and the right to act responsibly. As the ADR relates (currently) only to “international transportation of dangerous goods”, “Contracting Parties” may deviate in their national, non-border crossing transportation legislation from the ADR.

More suitable however, is the use of Article 4 of the main text of the ADR, (Quote of ADR, Article 4):

“

Article 4

- Each Contracting Party shall retain the right to regulate or prohibit, for reasons other than safety during carriage, the entry of dangerous goods into its territory.

“

(Unquote)

A few “Contracting Parties”, including the Netherlands, do allow liquid load securing to be used for “reasons other than safety” as per the provisions in Article 4 thereto. The reason applied is the mitigation of the vaporisation of dangerous liquids during their transportation and elimination of the emissions of such vapours. Such liquid load securing (and emission preventing) provisions do (of course: require to) comply with all relevant “requirements of the ADR”, as specified in ADR article 1.4.1.1.(see above).

Furthermore, “Contracting Parties” should possibly be more aware of their responsibilities regarding raising proposals for Amendments of the ADR with the UNECE, in accordance with Article 14 of the Main text of the ADR Agreement.

“Contracting Parties” are furthermore recommended to enforce load securing of all bulk liquid cargoes in the territory of their jurisdiction, irrespective of such liquids being classified as “dangerous” by the ADR or not. Liquid dynamics pose a safety risk in addition, but other than, toxicity, explosiveness of flammability, and equally undesirable.

OPPORTUNITIES OF ADR custodian, the “UNECE ITC”.

The ADR Contracting Parties may have agreed to the “desire to increase the safety of transportation of dangerous goods”, the question remains of how this “mission statement” has been translated into “Terms and References” for the UNECE ITC and how this institution realizes tangible safety increases wherever “desirable” and possible.

The author of this paper provided the UNECE ITC with a presentation, on the subject identical to the title of this paper, at the September 2018 ITC Joint Meeting. The relevant minutes of which are quoted hereinafter. This presentation, aiming at increasing “awareness and acceptance” on all topics as detailed in this paper, has not resulted (yet) in any safety increasing initiatives nor in any tangible actions thereto by the ILT. This is considered to be “rather unfortunate”.

Source: UNECE website

Besides the legislative mayhem described above, the UNECE ILT should be aware of additional, very serious consequences. Equally the ILT should accept these to be “unacceptable” and accept its responsibility for taking corrective actions (soonest).

One of these serious consequences is the record of too many unrightful court convictions of drivers of keeled-over tank trucks. These drivers, who are involved in these (often unilateral) accidents, are held fully responsible and thus accountable for causing the accident. Possible or even: “likely” contributions to the cause of the accident by liquid dynamics (or the proper functionality of for example “Roll-over Stability Systems”) receive no or insufficient (and, or incorrect) attention in related court cases. The author of this paper is increasingly being engaged as “expert witness” in court cases hereto. The awareness of, and controversy over, only one expert being available on a subject as serious and momentous as liquid transportation, baffles courts and cause these courts to be hesitant with the acceptance of the scientifically proven statements by expert.

The second example of a serious consequence of the lack of awareness of the contribution of liquid dynamics to the severity of very serious accidents involving mobile tanks that transport liquefied gas under pressure. Details hereto are provided above in this paper. The lack of understanding of load related physics in accident situations by law enforcement authorities should be a serious concern for the ILT.

The UNECE ITC is strongly recommended to initiate and subsequently support the increase and improvement of “awareness” of the safety aspects of sloshing liquids. The ILT is encouraged to promote dissemination of related knowledge.

Furthermore, the UNECE ITC is recommended to be unambiguously clear on the “acceptance” of all “scientifically proven” fundamentals. Finally, the UNECE ITC would act commendably in their unquestioned support of “ADR Participants” and “ADR Contracting Parties” exercising their rights and meeting their obligations on their ADR dedicated specifications, as detailed above.

Conclusion

The safety aspects of bulk liquid transportation have remained too long “obscure” largely due to the non-transparency of mobile tanks. The securing of any good other than bulk liquid has become mandatory by law, as means thereto became available and improved in quality. Now, proper securing of bulk liquids in a scientifically proven manner has become possible and products thereto have become commercially available, there appears to be an “indecisiveness” as to the legal status thereof.

This legal unclarity is partially explained by the lack of awareness of the consequences of sloshing of liquids during their transportation in mobile tanks and partially by the complexity of both “liquid dynamics” as well as of the legislation to which liquid load securing is, or should be, subject. The complexity of the legal requirements of bulk liquid transportation is further compromised and aggravated by the “baffle plate” requirement in the ADR, the legislation for the international transportation of dangerous goods. Baffle plates do not secure bulk liquid loads, these plates only mitigate sloshing and do so only in the driving direction of a tank truck or tank container and do so continuously (as these plates are permanently installed). The slosh mitigation by baffle plates results from an increase in energy dissipation by the liquid as it is forced through the openings in the baffle plates. This continuous energy dissipation results in a higher fuel consumption by the tank truck or truck loaded with a tank container and thereby results in unnecessarily higher CO2-emissions by the truck. The application of baffle plates is thus unsustainable and the legal requirements as in the ADR conflicts with various other, emission related legislation.

Liquid load securing, irrespective of its legal unclarity which only applies for international transportation of bulk liquids qualified as “dangerous”, has many advantages. Significant advantages result from direct safety improvements of current day-to-day bulk liquid transportation. Additional advantages result from accident mitigation improvements. Liquid load securing means using inflatable components also results in further environmental and economic advantages. The use of inflatable load securing components avoid the liquid to vaporize and thereby avoid the possible emission of such vapours. Besides the economic advantage of the reduced cost of fuel consumed, the cost of load securing means is (far) less than the cost of baffle plates while the lower weight of load securing results in a higher “pay-load” of the mobile tank. The application of bulk liquid load securing provisions make the transportation of bulk liquids more sustainable hence more desirable as when compared to transportation is a “sloshing” or “slosh mitigation” mode.

Liquid load securing should logically at least be allowed and encouraged but should, equally logically, be made mandatory in the long term, identically to the securing of any other cargo.

Further research of liquid load securing and verification testing, other than by the author of this paper, is strongly recommended, especially in view of the enormity of the subject. The author “desires” that (t)his paper has made its readers aware of the safety aspects of bulk liquid transportation, the possibilities to increase such safety aspects and that readers accept such and contribute to further increase of such awareness and acceptance, wherever one has a possibility thereto.

Acknowledgements

This paper owes credits to the following parties and occasions.

• The independent German certification body TÜV Nord for the certification of mobile tanks equipped with inflated components meeting ECE-111 and thereby ADR requirements. [12], [14].

• The independent Dutch testing and certification organization TNO for the validation of Slosh mitigating models. [10], [11]

• The Dutch fuel consumption specialist "Supro" for the targeted recording of fuel consumption during the tests. [13].

• The “Punt” company for the first practical fixed volume Cairbag application.

• The DEA (Deutsche Erdöl Aktiengesellschaft) on the application of the first variable volume ADR-based surge avoidance system, the beneficial "zero-emission" survey of its tests and the accompanying paper on "Cairbag" development, such as the DGMK Spring Meeting, 18/19. April 2018 in Celle (Germany).

• The National Transport Safety Board (“NTSB”) of the United States of America and her (now retired) board-member Dr. Bella Dinh Zarr for their and her awareness and acceptance of bulk liquid transport related safety aspects.

• The Australian National Transportation Council for their invitation as presenter of the subject of this paper at their 2018 Road Safety conference in Sydney.

• The UNECE for inviting author, as guest speaker to address the ITC “Joint Meeting on 17-21 September 2018.

• The first users, “Punt”, “Franz Fischer” (“DEA”), “Polyeco”,

“Wyss”, “Jansen Eupe” for their enthusiasm, awareness and acceptance.

REFERENCES

[1] Eenkhoorn, E.J. PhD (2017). Products to mitigate liquid sloshing, University of Twente, Enschede, the Netherlands, ISBN 978-94-6233-808-1. 22 November 2017.

[2] United Nations Economic Commission for Europe, European Agreement concerning the International Carriage of Dangerous Goods by Road (“ADR”), Geneva, 30 September 1957.

3] Ibrahim, R.A., Liquid Sloshing Dynamics, Theory and Applications, Wayne State University, Cambridge University Press, 2005, ISBN-13 978-0-521-83885-6

[4] European Parliament and Council, Environmental liability with regard to the prevention and remedying of environmental damage, Directive 2004/35/CE of 21 April 2004.

[5] BWBR 0025798, “Voertuigen-regelement”; Admission requirements for trucks on the road NL),

[6] European Parliament and Council, Control of volatile organic compound (VOC) emissions resulting from the storage of petrol and its distribution from terminals to service stations, Directive 94/63/EC of 20 December 1994, Official Journal L 365, 31/12/1994 Pages 0024 – 0033.

[7] "European Commission Transport". Road Safety: Best practice guidelines on cargo securing and abnormal transport. April 9, 2009. Retrieved November 16, 2009

[8] NEN- 12642 Securing of cargo on road vehicles, ICS 43.080.10, November 2006

[9] van Vollenhoven P., Prof. Mr., Tank-truck fires with dangerous goods, safety study, Council for safety, Den Haag 17 November 2006.

[10] J.M.J. Oostvogels, ir., An anti-slosh airbag for tank-trailers, TNO report 2006-D-R0441, 7 September 2006.

[11] J.M.J. Oostvogels, ir., An anti-slosh airbag for tank-trailers, real scale tests report, TNO report 2007- D -R0614/B, 6 juni 2007.

[12] Grunow, D., Kampmann, Th., Testing of the effects of the Accede inflatable component systems on the driving behaviour of tank-trucks, Technical report No. 944/7132512TÜV Rheinland Kraftfahrt GmbH, 26-8-2008.

[13] Taken, M., Fuel consumption: Accede inflatable component versus traditional tank containers, Supro Automotiv Engineering, 29-4-2010.

[14] Manter, U., Test report on load securing, Dynamic driving tests with tank-containers, Report LS0710890, TÜV Nord Mobilität GmbH & Co. KG, Juni-2010.

[15] EN 12 195

[16] www.accede.nl , film at „homepage“.

[17] https://youtu.be/fWY7jqQvfJU

[18] Technology Readiness Levels (TRL’s).

Author reference: Acc19105,

Revision 0.5 of 4th September 2020.