The duration of the functional performance requirement and of the life cycle specifications determine whether the design of the slosh mitigation product, irrespective whether the inflatable component is of a fixed or of a variable volume design, should be based on permanent or temporary installation on and in the mobile liquid holder.

Permanently installed inflatable components are more likely to be preferred in case of long term use of the mobile liquid holder for identical liquids, i.e. so-called “dedicated transportation”. Temporary or intermittently used inflatable components are more likely to be used in mobile liquid holders for transportation of liquids on an infrequent basis. The combination of permanently installed slosh mitigation products with, variable volume, horizontal cylinder shaped, inflatable components is foreseen to be applied commonly in tanks of tank trucks and trailers. The combination of temporarily installed slosh mitigation products with, fixed volume, horizontal cylinder shaped, inflatable components applied in tanks of tank containers, is equally expected to be applied frequently.

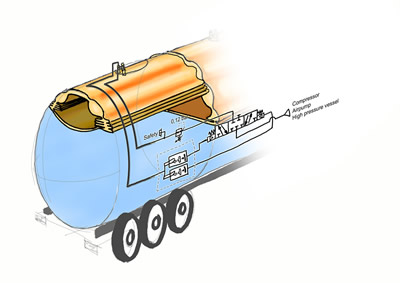

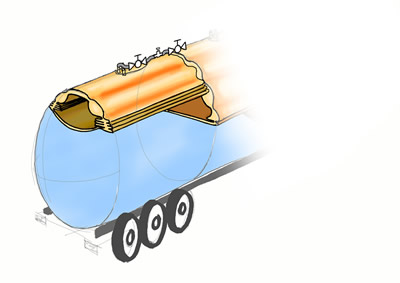

A temporarily used “short hose” (left) and a permanently complete (right) pneumatic sub-system. The remainder of the “short hose” pneumatics, could be positioned on a (dedicated) truck and/or in the (off-) loading infrastructure. (own design sketch).

The consequences of a “permanent or temporary” basis of design choice, are:

- Permanent installation allowing for tank modifications and for fixation of, parts of, the slosh mitigating system in or on the means of transportation, while an incidental or temporary installation preferably does not require such modifications nor fixations.

- Permanent installation and associated desired longer life-cycle of the slosh mitigation product requiring and justifying a higher quality membrane material to be used for the inflatable component.

- Temporary installation to require installation and removal aiding parts but not to require in-tank cleaning provisions compared to permanently installed slosh mitigation products

- The design of the interfaces with the liquid holder, the means of transportation or even the (off-)loading infrastructure, will differ for permanent and for temporary, incidental applications. Slosh mitigation product parts may be positioned other than on the mobile tank.

A “semi-permanent” slosh mitigation product

For some applications, the design basis could be optimized using a “semi-permanent” slosh mitigation product. The pneumatics could thereby for example be permanently installed on the truck, while the inflatable component is not. This may avoid unnecessary cleaning of the inflatable component after a transportation of liquid not requiring slosh mitigation. Alternatively, the inflatable component may be permanently installed inside the tank, being part of, for example, a tank container, to avoid removal and re-instalment operations, while the pneumatics are not permanently installed. The pneumatics may be installed on the means of transportation or the (off-) loading infrastructure, thus allowing to be used, alternatingly for more tank containers with an inflatable component only.

A design basis of an inflatable component combining at least one fixed and at least another variable volume chamber may cater for more than one purpose, at least one of which otherwise resulting in sloshing of the liquid.

A “multi-chamber” slosh mitigation product

The variable volume inflatable component as in the “Frans Fisher” case, see section 6.3, uses fixed volume inflated channels to ensure positioning and a variable volume main chamber to satisfy the requirement for the liquid volume range to be transported. The design of such an inflatable component can be typified as “multi-chamber”.

Avoiding axle over- or underloading, see above, may be resolved by a multi-chamber inflatable component. One chamber dedicated to the functionality of required avoidance of axle over- or underloading.

The basis of design of a multi-chamber inflatable component may even allow for a liquid product holding chamber (or a stand-alone component).

The necessity to keep a vapour phase inside the tank conflicts with the slosh mitigation requirement to minimize the free air volume inside the tank. A vapour accessible space inside a mobile liquid containment system is likely to be mandatory, for example, in case of LNG transportation as the vapour allows for boil-off, as well as control of temperature and pressure of the LNG cargo in a LNG carrier. The basis of design may allow for such vapours to be collected in a dedicated chamber of a multi-chamber inflatable component.